- HOME

- Technology

Production

plant

PRODUCTION PLANT

Designed specifically for the needs of our business. Planned to organize the company’s production, office and warehouses in one place. Built in a carefully selected location to ensure smooth transportation and communication in commercially most important directions. The plant’s total site area is 20,000 m2.

- 3,500 m² of production area where 11 product groups are created

- 2,500 m² of covered warehouse space

- 5,000 m² of open warehouse area

- 500 m² of office and social space

TECHNOLOGIES

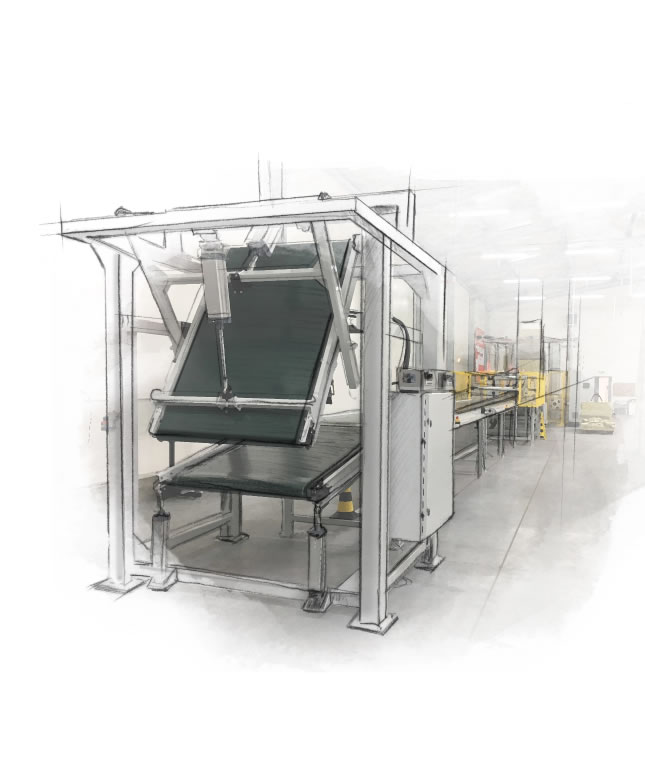

Production lines

5 modern perfectly controlled production lines with a high degree of automation, designed with optimal flow (Lean Manufacturing) in mind. Characterized by high efficiency and repeatability of production processes at a consistently high level of quality.

- Maintenance according to TPM principles

- product design and processing supported by CAD/CAM systems

- technological processes managed by PLC class controllers

ISO 9001

According to the adopted Rohhe’s policy, the ISO 9001:2015 system is an inviolable part of the Integrated Management System which shapes the coherent unity of the company’s structure and operation. Our goal is the continuous pursuit of excellence.

As part of the system, we ensure constant and systematic quality control which includes the areas of production, technology, procurement and sales. For this reason, we have implemented a detailed Factory Production Control (ZKP) program which complies with CPR standards for EN14303 and MED standards for 3.13 and 3.18a/d/f.

In the area of building regulations CPR/EN14303, the Factory Quality Control is carried out in the highest regime – System 1, requiring external supervision confirmed by Certificates of Constancy of Performance, carried out by notified certification bodies: IMBiGS No. 1454 and PCBC No. 1434.

In the area of MED/SOLAS marine regulations, the Factory Quality Control is also carried out in the highest regime – so called Module D, subject to external supervision and EU Production Quality Assurance Certificate, exercised by PRS No. 1463.

The Factory Production Control program also includes elements of parameter control and in-house requirements that exceed those of the above systems. Quality control at Rohhe consists of three stages: control of raw material at the entrance to production, continuous control of parameters during the production process and testing of finished products in the laboratory. Such a comprehensive system enables effective control and for years has allowed us to maintain a constant level of quality of our products.