Mineral wool pipe section

r.Heat N

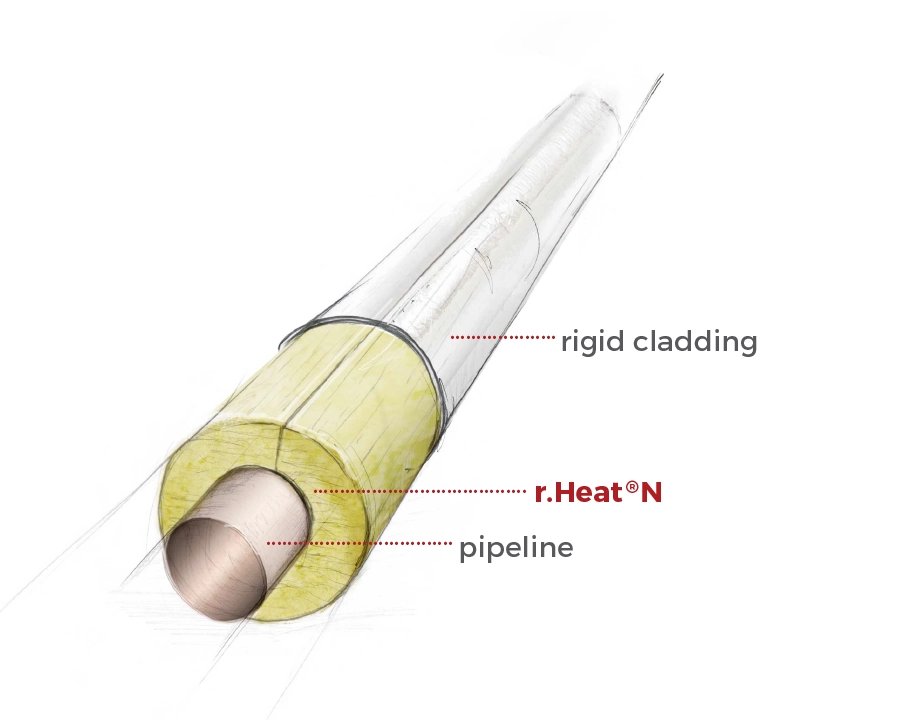

r.Heat N is a pipe section made of mineral wool without cladding. The wool used is characterised by high temperature resistance (up to 300°C) and water absorption resistance (≤ 1 kg/m²). Thanks to the special fibre composition, the product is characterised by high longitudinal stiffness, mechanical strength over the wall thickness and optimal thermal insulation properties. r.Heat N has a longitudinal installation slitting and an internal technological notch facilitating installation of the product on the pipeline.

Application

r.Heat N is intended for thermal, acoustic and fire protection insulation of piping systems.

The product is used in industrial and building installations in applications requiring additional external shielding. The product is fit for working both with rigid cladding, such as metal sheets, and flexible cladding, e.g. in the form of a multilayer UV resistant film. The compact structure of the wool used provides secure and durable support for the cladding. Low chloride ion content (CL10) reduces the risk of corrosion of the insulated elements. The 20% longer length of r.Heat N (1,2 m) increases the efficiency of insulation work, contributing to lower labour costs.

-

Product structure

-

Pipeline insulation - rigid cladding

-

Pipeline insulation - flexible cladding

-

Pipeline insulation - without cladding

Advantages of the shape preservation system

r.Heat N has a unique system of maintaining the round shape of its internal diameter. Due to the special technology used to shape the walls of the pipe section, the loss of material within the assembly gap does not affect the round shape of the internal diameter. Thanks to this property, the r.Heat N pipe section installed on the pipeline is tightly closed at the point of cut and ideally adheres to the pipeline, which directly counteracts the occurrence of “cold bridges”. This is crucially important for installations with diameters (DN) of more than 3 inches.

-

Typical pipe section

-

Pipe section with shape preservation system

Technical data

The value of declared thermal conductivity (Lambda D) at selected mean temperatures

Change the thermal conductivity according to the avarage temperature

Packing method

Cardboard boxes of r.Heat N pipe sections are laid vertically on a wooden pallet (0.8 x 1.2m) in two layers. Depending on the size of the product the pallet holds 12 boxes (0.4 x 0.4 m) or 8 boxes (0.6 x 0.4 m). The pallet is protected by auxilary LDPE hood on top and additionally wrapped in stretch foil. This packaging method fully protects the product from demage during transportation and during warehouse moves. It also allows for the safe stacking of factory-secured pallets in two layers.

All r.Heat N pipe sections are packed in cardboard boxes. The smaller boxes are 0.4 x 0.4 x 1.2 m, while the larger ones are 0.6 x 0.4 x 1.2 m.

Each box features two special, perforated slit openings giving convenient access to its contents. Opening the slits does not affect the structure of the side walls of the box.

To facilitate the transportation of individual packages, handles are cut out on the sides of each box. The box provides viable protection against both dirt and mechanical damage.